Insulated Precision Phillips Screwdriver VDE 1000V

Price 429 INR/ Unit

Insulated Precision Phillips Screwdriver VDE 1000V Specification

- Features

- Insulated, VDE Certified, Ergonomic Handle, Precision Tip

- Surface Finish

- Polished and VDE Insulated

- Voltage

- Tested Up To 1000V

- Function

- Safe Electrical Fastening and Loosening

- Gauge

- Applicable for Precision Electrical Screws

- Motor Power

- N/A (Manual Tool)

- Tensile Strength

- High Tensile Strength for Electrical Work

- Power Source

- Manual

- Grip Type

- Anti-Slip Insulated Grip

- Tool Type

- Precision Phillips Screwdriver

- Material

- VDE Certified Insulated Steel

- Handle Material

- Ergonomic Plastic with Insulated Grip

- Shape

- Phillips Cross Head

- Dimension (L*W*H)

- 150mm x 35mm x 25mm

- Packaging

- Supplied in individual blister pack for retail

- Weight

- Approx. 30g

- Magnetized Tip

- No; designed for precision work in electrical environments

- Application

- Suitable for electrical equipment, control cabinets, and circuit breaker panels

- Tip Type

- Precision Phillips #0

- Temperature Resistance

- Withstands up to 70°C Ambient

- Safety Rating

- Meets International Electrical Safety Standards

- Color

- Red/Yellow handle for high visibility

- Insulation Standard

- VDE Certified up to 1000V for electrical safety

- Corrosion Resistance

- Rust-Proof Treatment on Metal Parts

Insulated Precision Phillips Screwdriver VDE 1000V Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Domestic Market

- All India

About Insulated Precision Phillips Screwdriver VDE 1000V

Insulated Precision Phillips Screwdriver VDE 1000V

VDE/GS certificated

S2 material blade, entirely hardened and tempered

Chemically blacked surface

Grip and sleeve manufactured according to EN60900

Ergonomic shape handle

Packing: blister card

Size PH00x50mm, PH0x50mm, PH1x50mm

Reliable Safety for Electrical Work

Built to VDE standards and tested up to 1000V, the screwdriver ensures maximum electrical safety for both professionals and DIY users. Its insulated blade minimizes the risk of electric shock, making it suitable for use with live electrical components found in control panels and wiring systems.

Precision Engineering for Confident Handling

The Phillips #0 tip is crafted for precise engagement with small fasteners, reducing the risk of stripping screws during delicate assembly or disassembly. The high-tensile insulated steel shaft, finished with rust-proof treatment, supports lasting performance in demanding electrical environments.

Comfort and High Visibility Design

Featuring an ergonomic red/yellow plastic grip, the screwdriver delivers excellent handling and control even in slippery conditions. The anti-slip, insulated handle design enhances user comfort, while the high-visibility color scheme ensures the tool can be easily located in cluttered toolboxes or workspaces.

FAQ's of Insulated Precision Phillips Screwdriver VDE 1000V:

Q: How does the VDE certification ensure electrical safety with this screwdriver?

A: VDE certification confirms the screwdriver has undergone rigorous testing for insulation and structural integrity, ensuring safe use with voltages up to 1000V in electrical applications. This standard is internationally recognized, providing assurance of the tool's reliability during electrical maintenance or installations.Q: What makes this screwdriver suitable for use in control cabinets and circuit breaker panels?

A: Its precision Phillips #0 tip allows for reliable fastening and loosening of small electrical screws often found in control panels and breaker assemblies. The insulated construction protects users from potential electric shock while working with live or sensitive components.Q: When should I use a non-magnetized, precision screwdriver for electrical equipment?

A: A non-magnetized precision screwdriver is ideal when working near sensitive electronic or electrical components where magnetic fields could cause malfunctions or data loss. Its accurate tip size ensures precise control in tight or delicate environments.Q: Where can I use this insulated screwdriver safely?

A: You can safely use it on electrical equipment, inside control cabinets, when working with circuit breaker panels, and for general electrical maintenance jobs where voltage exposure is possible, provided the tool's maximum insulation rating (1000V) is respected.Q: What is the process for maintaining the screwdriver's insulation and performance?

A: To maintain optimal insulation, regularly inspect the shaft and handle for damage, fissures, or wear. Clean the tool surface with a dry cloth; avoid using harsh chemicals that could degrade the VDE insulation, and always store it in a dry, secure place after use.Q: What benefits are provided by the screwdriver's anti-slip insulated grip and high-visibility handle?

A: The anti-slip insulated grip gives you better control and comfort, reducing hand fatigue during prolonged use. The bright red/yellow color scheme makes the tool easy to spot, minimizing the chances of accidental tool loss in busy electrical work environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Insulated Hand Tools Category

Insulated Wire Stripper 1000V

Price 1206 INR / Unit

Minimum Order Quantity : 1 Unit

Grip Type : Ergonomic Nonslip

Power Source : Manual

Tensile Strength : Up to 1000V Rated

Dimension (L*W*H) : 170mm x 50mm x 18mm

Insulated Precision Torx Screwdriver VDE 1000V

Price 429 INR / Unit

Minimum Order Quantity : 1 Unit

Grip Type : Ergonomic, Nonslip

Power Source : Manual

Tensile Strength : High Tensile Strength Suitable for Tough Applications

Dimension (L*W*H) : Approx. 150mm x 25mm x 25mm

Insulated Ring Wrench VDE 1000V

Price 1996 INR / Unit

Minimum Order Quantity : 1 Unit

Grip Type : Ergonomic Nonslip

Power Source : Manual

Tensile Strength : High

Dimension (L*W*H) : Varies by size (Standard: 200mm x 40mm x 20mm)

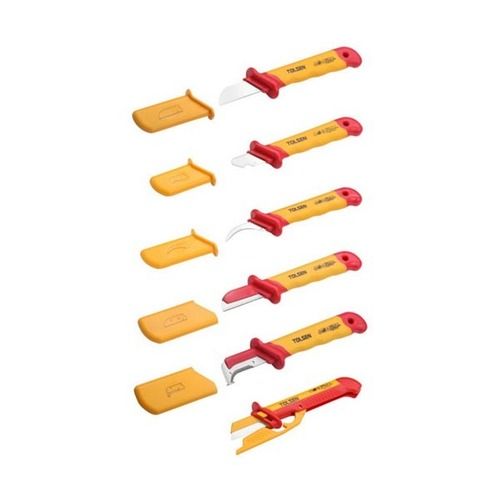

Insulated Injection Knives VDE 1000V

Price 429 INR / Unit

Minimum Order Quantity : 1 Unit

Grip Type : Ergonomic Nonslip Grip

Power Source : Manual

Tensile Strength : Up to 1000V Insulation Tested

Dimension (L*W*H) : Approx. 180mm x 20mm x 15mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry